A lot has changed ever since the Covid-19 pandemic hit the world. A histrionic shift in consumer purchasing behaviors and increasing stay-at-home tendencies put a huge strain on supply chains in the CPG and FMCG industries. Statistics reveal that supply chain costs for several CPG companies have escalated by almost 50%. More so, many of these companies have felt the need to allocate double the average resources to maintain the needed supply chain flexibility. Staggering, right?

All this has led CPG industry leaders to rethink their traditional supply chain practices and adopt the latest technologies to maximize supply chain visibility.

In this blog, we will explore how CPG firms can improve supply chain visibility and flexibility with distributed systems, ensuring optimal demand planning and better customer satisfaction.

An Introduction to Distributed Systems

Also known as distributed computing, a distributed system can be understood as a collection of autonomous components located in multiple locations and on different machines that exchange data with each other to achieve common goals.

You can think of a distributed system as a single interface that works together to maximize resources and mitigate failures, so if one component fails, it doesn’t impact the availability of the service.

With distributed management system, supply chains can be made much more resilient. Distributed systems can collectively manage and monitor the entire supply chain network, including order collection, inventory management, delivery management, and payment collection. Thus, it can help to enhance the operation’s visibility and increase process transparency with real-time responses.

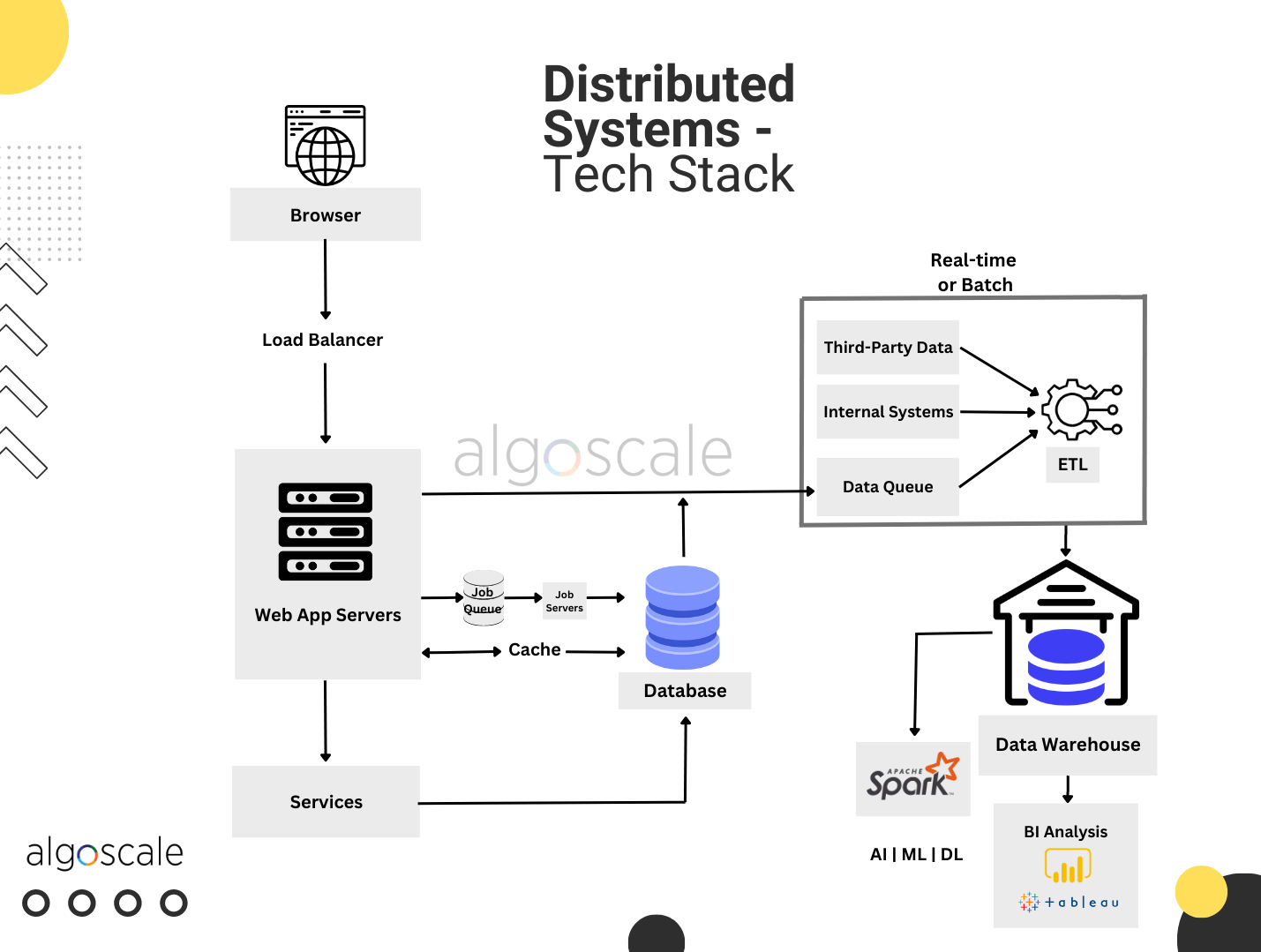

Below is an image showcasing the tech stack involved in distributed systems.

Different Ways Distributed Systems can help to Power Smart Supply Chain Operations in the CPG Industry

In the past few years, there has been an increased dependency on eCommerce channels. Besides, the pandemic fuelled newer and greater customer expectations such as personalized shopping experiences and same-day deliveries.

So, to keep up with these customer expectations, CPG firms have to launch renewed processes and reinvent their supply chains to decrease time-to-market. This has been possible with distributed systems. These systems have the potential to power connected and agile supply chains that bring increased resilience to the CPG sector.

Here are some ways CPG companies can gain a competitive advantage and maximize supply chain visibility with distributed systems.

- 360-degree visibility

In most CPG companies, supply chains are extremely intricate. A large part of relevant information, such as crucial inventory data and delivery updates, exists in silos. Also, there is a lack of process coordination among the different vendors which results in inefficient and manually-intensive supply chains.

What businesses truly require is a holistic view of consumer demand, inventory, and shipments, which is only possible with an intelligent supply chain powered by distributed systems. CPG companies can implement next-gen data-capturing technologies such as RFID, BLE, UWB, etc. for inventory tracking and planning. They can enjoy increased visibility into the supply chain operations that allow them to make emergency plans in case of unanticipated situations such as delayed shipments. This can eventually nurture relationships between CPG firms and their suppliers.

- Optimization of processes with real-time actionable insights

The CPG company supply chain is a complex network of multiple suppliers that require accurate, timely, and actionable insights. Additionally, the volatile market conditions and increasing consumer demands need high efficiency to react to altering network conditions.

With distributed system management, CPG companies can digitalize their entire value chain and obtain meaningful insights that facilitate dynamic decision-making. They can easily monitor every transaction across the network to enable the digitalization of the shipment procedure. Also, easy tracking of package movements can help to pinpoint delays, and even enable CPG companies to intervene in time and take measures to expedite the delivery.

- AI-enabled cost reduction

The supply chain accounts for a significant percentage of a company’s sales. CPG firms can leverage Distributed AI to detect and eliminate wasteful hold-ups that can reduce operational costs.

AI-enabled intelligent supply chains can easily observe the complete scope of company processes and evaluate the direct cost linked with each process. This enables CPG companies to strategically enhance cost savings in the following ways:

- CPG companies can streamline their workflows which include managing activities like generating invoices, organizing deliveries, responding to customer queries, etc. All this can result in reduced transactional costs.

- CPG companies can implement better forecasting and replenishment between retailers and manufacturers. This can avoid duplication of orders or numerous iterations in the supply chain which helps to bring down the network costs and boost profitability.

- Intelligent supply chains can track and monitor changing consumer behavior to avoid any inventory stockpiling cases.

- Mitigating risks with predictive analytics

All companies nowadays have to deal with rapidly shifting consumer demands and preferences. And this makes the process of forecasting extremely difficult and challenging. As per statistics, inaccurate forecasts cost 30-50% excess inventory which adversely impacts a company’s bottom line. Furthermore, inaccurate forecasting leads to stock shortages that affect the customer’s shopping experience.

An intelligent supply chain powered by distributed systems employs predictive analytics that allows CPG companies to optimally forecast consumer demands and optimize inventories in real-time. They can develop robust and effective plans of action that deliver success across their supply network and easily identify any patterns in the supply chain or distribution network.

How Can Algoscale Help?

By now, we know that agile, robust, and intelligent supply chains are the driving force for resilient company operations. Thus, CPG companies need to consistently assess and evaluate their supply chain operations to identify any gaps and boost profitability.

At Algoscale, we enable CPG companies to take charge of their business supply chain and keep up with dynamic business trends and consumer patterns. We provide distributed system management solutions that provide actionable insights across markets and consumers, helping CPG companies make better and more informed decisions.